/ES REPORTAGE

Dust Money

Indonesia is the beating heart of nickel production for the green transition, but the industry is hiding a raft of dirty practices

This piece was published in collaboration with The Gecko Project.

The Bajau village at Morombo was created by a shipwreck. Thirty years ago, the community lived a nomadic existence on flat-decked “sope” houseboats from which they spearfished and dove for clams and conchs in the waters off Sulawesi, the orchid-shaped island at the center of the Indonesian archipelago.

Then, in the late 1990s, their flotilla was caught in a storm, smashing the boats and leaving them homeless. Around 40 families settled, temporarily, in this small-mouthed bay on the eastern coast of Southeast Sulawesi, building stilt huts over the water to wait until they could afford to buy new vessels and return to the sea. Like many of Indonesia’s Bajau communities — members of a traditionally nomadic, maritime ethnic group — they ended up staying on land. Traditional boatbuilding has all but died out and the government offered them incentives to settle down. Despite being becalmed on the shore, they were able to recreate their old livelihoods.

The shore “was still green, bright. The water was clear,” says Diana, one of the last generation in the village to be born at sea. “We could collect clams. We could fish with spears.” It wasn’t the same as life on the sea, she says, but they were happy enough. Diana is a taut, wiry woman in her 70s with platinum hair and crystal blue eyes. In her house, suspended a few feet above the water, she speaks with a barely restrained fury as she describes how the refuge they found on the shore has been taken away from them.

Five years ago, the nickel rush came to Morombo. First, a few pits opened inland of the village, cutting down trees and stripping back the topsoil to expose the orange dirt below. Gradually, the mines bled together, congealing into an orange ring that completely engulfed the village. To reach the settlement now means driving first along flooded and broken tracks through oil palm plantations and then through the mines themselves. The sodden path threads between wide concave pits, the whole landscape a rusted monotone overseen by long ranks of Komatsu diggers and the low, loping forms of stray dogs. An access road for the mine runs above what passes for a main street in the village.

Distant explosions echo around the bay. Dust rises out of the pits and blows over the village, settling on every structure. The bay itself has turned the same orange as the land as silt washes down from the denuded hills. Fishing trips yield dwindling catches and the community is no longer self-sufficient, relying instead on what they call “dust money” — compensation from the mining companies that totals just 400,000 rupiah ($25) a month per household — barely 15% of the region’s median monthly salary.

“We’re half dead on land,” Diana says. “Everything is broken. The sea turned brown. We’re eating dust.”

The mines around Morombo are part of a vast new frontier for Indonesia’s extractives industry. Nickel has become an obsession of the government in Jakarta, which has declared the mineral to be the foundation of a whole new economy for Indonesia. The mineral is an important component of stainless steel, but also of the batteries used in energy storage and electric vehicles (EVs). That makes Indonesia’s nickel reserves — the largest in the world — a resource of global significance, an opportunity for the country to position itself astride the international green transition.

This boom isn’t just a feature of rising global demand for nickel; it’s a deliberate, engineered rush, pushed by the government via a policy of deregulation, subsidy and political support for smelters and miners. It’s a political project that has delivered, in the form of giant new industrial complexes that have sprung up across the island. Tens of billions of dollars have flowed into Indonesia, mostly from China, and tens of thousands of Indonesians now work in the industry’s furnaces, power plants, docks and quarries.

But the sheer speed of this frontier’s growth and the economics behind it have brought it into conflict with communities and placed pressure on ecosystems and landscapes. To feed the furnaces at the smelters, hundreds of thousands of acres of land have been licensed for exploration, much of it occupied by the country’s dwindling rainforests or close to communities that were already among the poorest in Indonesia. Millions of tons of coal are being burned to power the smelters, reversing the country’s progress on reducing its carbon emissions. To head off dissent, the government has rewritten the law to prevent Indonesians from protesting against the industry and even deployed the military to protect these new “strategic” assets. In the smelters, injuries and deaths are mounting, as is the tension between locals and the Chinese companies that have driven the boom.

It has been almost five years since the boom began in earnest. In the meantime, the economics of the electric vehicle industry have shifted, as have the currents of geopolitics, with profound implications for the supply chains of critical minerals. A new government has taken power, bringing with it new fears of authoritarian creep and oligopoly. And the urgency to cut carbon emissions is only increasing, driving governments all over the world to take increasingly drastic measures to decarbonize their supply chains. The compromises made to build the industry are piling up and the nickel reserves are dwindling.

Sulawesi is the heart of Indonesia’s rush for nickel. Mines are carved into the hills, forests and coasts of what used to be called the Spice Islands.

New Lines Magazine and The Gecko Project traveled 1,200 miles through the nickel frontier to understand how the industry is reshaping the landscapes and societies of Indonesia.

We wanted to explore the bargain behind the nickel rush, which promises jobs, wealth and green growth, in exchange for short-term environmental damage and social conflict.

Chapter 1 | Power Play

The village of Torobulu has been retreating in stages. The settlement, on the southern coast of Southeast Sulawesi, is clustered along a trunk road that branches off the main artery from the capital, Kendari. On the western edge, houses and businesses line the roadside; behind them sit small rice paddies and orchards. On the eastern side, the fields have mostly disappeared into familiar rust-colored pits.

Six years ago, a local mining company, Wijaya Inti Nusantara (WIN), acquired land on the eastern edge of the settlement and began to dig. Its excavations crept inexorably toward people’s homes. “From the beginning, their methods were reckless,” says Ayunia Muis, who lives close to one of the pits. When the boundary of the mine started to encroach on an elementary school near her home, she and some friends went out to protest. Nothing changed — the mine, she says, made promises to villagers and local leaders, and the opposition to it ebbed away. “The eastern part of Torobulu is mostly wrecked because of what the company did through lobbying,” she says. “Then in 2023, when the land in the eastern part was depleted, the company wanted to come back into the residential areas.”

We meet Ayunia underground in the storeroom of a motorcycle repair shop, surrounded by metal shelves loaded with machine parts and lit by a bare bulb hanging from the ceiling. Ayunia is petite and moon-faced in a dark-blue hijab, soft-spoken at first, but she winds up to a forceful tone as she settles into her subject. Gathered around her are a dozen dedicated opponents of the mine — among them one former employee of WIN, now among the more vitriolic of its detractors. He nods along as Ayunia talks.

Since the mine started growing again, the damage — and the conflict — have escalated. Dust settles on homes and fields, wrecking crops. Rainfall causes mud to slip into the sea, disrupting the fisheries and shellfish harvest. As in every coastal village that New Lines and The Gecko Project visited downstream of nickel mines, Torobulu’s fishers have to travel much further to chase dwindling catches. In the dry season, the village, which relies on a single spring, ran out of water when the source suddenly dried up. When Ayunia and some of her neighbors went to investigate, they found that a deep mining pit had been dug nearby and all their water had flowed into it. Another pit was opened up, less than 100 yards from homes, right underneath the cell tower in the village.

Again, they decided to protest, confronting mine employees and demanding to see their permits. This time, they were met by police and soldiers. Video footage of the protest appears to show a melee, with security officers in plain clothes trying to wrestle cellphones from villagers. Soon after, the protesters started receiving summons from the police. Multiple residents were questioned by police and two were charged with obstructing the mine’s activities. They were later acquitted.

WIN did not respond to a request for comment but has previously stated to local media that its activities have not damaged Torobulu’s water sources, affected residents’ ability to farm and fish or polluted the local area. It said that it had mined close to residential areas because residents had asked it to do so and that its activities are supported by “almost the entire community of Torobulu.”

Unbeknownst to Ayunia, between her first protest in 2018 and her second in 2023, the Indonesian government had passed a new law effectively forbidding people from standing up to mining companies. Article 162 of a new mining code, passed in 2020, makes it illegal to “hinder or disturb” mining operations in any way — wording so broad that it can be contorted to shut down almost any opposition. It’s just one change among several that have shifted the balance of power on the ground further away from communities and toward mining companies, who often seem able to operate beyond the bounds of regulation with impunity.

The nickel mines of Southeast Sulawesi don’t form a single frontier sweeping across the land but rather patches of rust creeping slowly together. They are scattered through the landscape, hidden by high fences and mounds of dirt, with access guarded by private security and, occasionally, uniformed military police. Nickel ore is found close to the surface and the pits are dug broad and shallow, miles wide in places. Viewed from a satellite or drone, they are areas of negative space on the image, featureless and bare between the textured green and blue of forests, cocoa and coconut plantations, spice orchards and wide mirrored rice paddies.

An analysis by Mighty Earth, an environmental nongovernmental organization, found that almost 300 square miles of forest have been cleared to make way for nickel mining, at a conservative estimate. That figure could yet rise significantly. Nickel mining permits covered more than 3,000 square miles by early 2024, an official in the Ministry of Energy and Mineral Resources told CNBC — an area 10 times the size of Singapore. Mighty Earth’s analysis suggests there are nearly 2,000 square miles of forest left inside these concessions.

The consequences of this expansion are not hard to find. Driving through the flat plains of rice fields in Kolaka Regency in Southeast Sulawesi, we see a farmer slopping gobbets of orange mud by hand from the paddy to the bank. Since the mines on nearby hillsides started to expand over the past two years, silt has flowed into the fields whenever it rains heavily. In the coastal village of Lapau-Pau, we meet seaweed farmers who shifted to aquaculture when their crops collapsed, only to see their fishponds stained red by mine runoff. The juvenile fish they stocked their ponds with died in droves; they were lucky if half survived.

The encroachment of mining into communities and the erosion of the economies that have sustained them inevitably create conflict. We visit nine communities near mining sites in Southeast and Central Sulawesi. In each, locals say they have ended up demonstrating against the mines. Their demands were often modest: dust money, compensation or jobs. At times, the confrontations turned violent.

At Lapau-Pau, villagers blockaded access roads leading into a nearby mine, demanding compensation for pollution and lost incomes. At one of the protests last year, things spiraled out of control and at least one protester was jailed after they used machetes to hack through a rope securing an ore barge to the shore, leaving it floating free in the harbor. In an attempt to get some money back from the mining companies, the village head, Darman, who only uses one name, used his powers under Indonesia’s devolved government rules to impose a levy on ore barges passing through his waters, as a way to extract compensation from a nearby mine. He was arrested earlier this year and charged with extortion. The case is still pending.

So-called “kriminalisasi” — criminalization — has become a feature of Indonesian civil society’s battles with the extractive industries. Hard-won freedoms to protest, organize and assemble have been rolled back over the last decade, allowing companies to make use of a compliant legal system to shut down opposition. Sometimes, they are creative in their application of the law.

In one notorious case in 2020, fishers protesting against the dredging of their waters by a construction company in Eastern Sulawesi were handed envelopes of cash by a company representative. One of the fishers tore the envelope in protest and was arrested for “defacing the rupiah.” In Java, in 2018, activists protesting against a gold mine were charged under Cold War-era anti-communist laws.

Criticizing powerful people or companies often opens activists up to charges under criminal defamation laws or online communications laws. “The criminal code has more than 30 criminal defamation articles ranging from spreading fake news to defaming someone’s name, defaming the country, defaming the flag, defaming a government official,” says Andreas Harsono, who researches Indonesia at Human Rights Watch. “The bad thing about these criminal defamation laws in Indonesia is that one who filed the lawsuit need not prove that the accusation is wrong.”

Two students, Christina Rumahlatu and Thomas Madilis, are currently facing criminal defamation charges after joining a protest in Jakarta that called for better environmental protections and workplace safety at the Indonesia Weda Bay Industrial Park, a nickel processing facility in North Maluku province. The pair allegedly defamed the retired general and mining investor Suaidi Marasabessy, who protesters said bore some responsibility for issues at the facility.

Article 162 of the new mining code has given companies another tool. Under the code, from the moment a company gets a permit to mine, it is protected from anything that could be called “disruption” to its operations. The wording of the law means it could be applied to almost anything, from protests, lobbying and investigative work by journalists and civil society to social media campaigns.

Mines and industrial facilities that are granted the status of a National Strategic Project by the government are given even more legal protections. “You cannot take photos of a strategic project. They are more or less considered to be similar to a military facility,” Harsono says. “The range of possibilities to criminalize the activists is much bigger.”

Anything designated a national strategic project is typically granted military protection and special status. Soldiers turn up to support police and mine employees at protests.

Security around sites marked as strategic projects is overt. There are guards in fatigues, some with military badges, others with what look like private security logos. Some sites have large signs that warn that flying drones is prohibited.

Private security personnel at these projects have the right to arrest people, although they have to hand them over to the police. “If you have this status, you basically can have your own private police,” Harsono says. Many security companies are run by retired military personnel, which deepens the links between the extractives industry and the armed forces.

For companies and officials willing to operate outside the purely legal mechanisms available to them, there are contractors willing to perform off-the-books services. Several of the activists and community organizers we spoke to in Sulawesi say they have been targeted by local gangsters, who threatened them or their families, and warned communities against taking action.

Melky Nahar, the national coordinator of the mining advocacy network Jatam, says that civil society organizations are bracing for worse to come. In February, Indonesians elected a new president, Prabowo Subianto, a former general who was accused of overseeing human rights abuses during his military career, whose family wealth is based partly on mining, and whose business interests include a private security firm that offers its services to the nickel industry. Prabowo, who took office in October, has indicated that he intends to continue former President Joko Widodo’s administration’s push for nickel. “The focus now is on how to prepare for the new regime,” Melky says.

In Torobulu, Ayunia leads us to the mining pit nearest her home. It is a short walk, past one of the whitewashed towers that locals use to farm bird nests, which plays the sound of twittering birdsong through speakers mounted high on its walls. There is no fencing and the hole, a carved scoop 100 yards long and 10 deep, appears to be inactive now. Standing on the edge of the pit, the villagers point out local landmarks: there, 20 yards away, the cell tower; over there, behind some low trees, a school.

The amount of money and power arrayed against opponents of the mining industry is daunting. The villagers in Torobulu have been confronted by private security and military personnel in their own community. The arrests of Ayunia’s neighbors and the legal threats against others have meant that the mine’s opponents in Torobulu have dwindled to around 30 people. There are parts of the village that Ayunia has been warned against visiting. Her grandmother received threatening phone calls. But those who remain — the hard core who meet in the bike mechanic’s shop — are staying the course. “East Torobulu is completely destroyed,” Ayunia says. “That’s what makes our group solid. Because we have learned the lesson that if the company mines at North or West Torobulu, it will destroy our village.”

Ayunia has been broadcasting on TikTok and Facebook Live to show others in Indonesia the impact of the mines. Even that has brought her attention from the authorities. Recently, she posted a long video on Facebook describing the conditions in Torobulu. That evening, a police officer called her and tried to discourage her from posting in the future.

She is under no illusion about the fact that the odds are stacked against her. “We’re seen as a small power,” she says. “Sometimes I feel scared, but then again, everything I’ve done is for my future.”

The ore that comes from the mines of Southeast Sulawesi is shipped north, to giant industrial parks.

This infrastructure forms part of Indonesia’s national strategy to develop the sector, which it has backed with changes to the law and tax breaks that have attracted massive investment, mostly from China.

Chapter 2 | Virtue Dragon

The smelters of the Virtue Dragon Nickel Industrial Park are a pair of smoldering fortresses squeezing the town of Morosi between them. They are surrounded by wire fences and high concrete walls, topped with broken glass in places. A rough ring road sweeps around the town and its orbital paddy fields and fish farms, watched over by stilt huts, many of them now derelict. In the daytime, the park is occupied by thousands of staff — mainly men — in identical gray overalls and yellow plastic helmets. Tankers move slowly through the streets spraying water on the roads to keep the dust down. At the main intersection, workers direct traffic with red flags, clearing the way for convoys of trucks hauling ore. Emblazoned on the sides of ore hoppers and security trucks is the slogan: “SAFETY FIRST.”

Virtue Dragon Park, a couple of hours’ drive north of Southeast Sulawesi’s regional capital, Kendari, was one of the foundation stones of Indonesia’s nickel rush. Its main backer is the Chinese steelmaker Jiangsu Delong, which operates two smelters in the park, one called Virtue Dragon, the other Obsidian Stainless Steel. Jiangsu Delong was an early mover in the industry, one of dozens of Chinese companies that have been attracted to Indonesia by cheap nickel and government incentives. Today, Chinese companies make up the bulk of the foreign investors in the industry.

Ujang arrives at our meeting still in his Obsidian Stainless Steel uniform, stained with coal dust after a full day’s shift. Ujang, who speaks with us on condition of anonymity to avoid retribution from the company, works at the coal burner that powers the facility, on a team that transports hundreds of tons of coal from its storage hangars to its furnaces every day. The dust clings to everything. Even outside the facilities, the air is thick and rasps the throat. Inside, it’s hazardous, but Ujang’s only protection is a thin paper mask, of the kind that you can buy for a few cents in a convenience store. His chest feels tight all the time, he says, but when he and colleagues complained to their employers about persistent respiratory problems, all they were given was a Chinese herbal tincture.

Injuries are common at Virtue Dragon Park, he says. Over the last two years, Ujang says one of his colleagues had an arm amputated after it was caught in a conveyor belt. Another fell 80 feet from a gantry. A Chinese worker died after falling into a tank of boiling water. In 2022, an Indonesian worker was performing repairs inside one of the machines used to dry coal at the loading jetty. “His friend didn’t know he was inside and turned the machine on. He literally spun inside the drying machine,” Ujang says. “He died instantly.”

Corroborating this is difficult, as the company threatens to punish workers if they post on social media about incidents at work, according to Ujang and several other employees of Jiangsu Delong-owned companies in Southeast and Central Sulawesi to whom we spoke. Of the five workers for VDNI and its sibling companies who spoke to New Lines and The Gecko Project, all had stories of injuries and fatalities.

Jiangsu Delong did not respond to multiple requests for comment.

The nickel processing sector has been beset by allegations of labor rights violations and safety failures that have caused deaths, injuries and sickness in and around the smelters. Labor rights activists and workers at industrial facilities operated by Chinese investors say that the Indonesian government is turning a blind eye to rule-breaking at the smelters, allowing their owners to cut corners on safety standards and environmental protection. That has left a simmering discontent among workers and local communities, which has occasionally flared into violence.

At Indonesia Morowali Industrial Park (IMIP), the giant estate in Central Sulawesi that is the spiritual home and practical center of the Indonesian nickel rush, one accident has stuck in the public consciousness. In December 2023, a repair crew was working on a furnace at Indonesia Tsingshan Stainless Steel (ITSS) when a leak ignited blowtorch canisters. Twenty-one people died in the explosion and dozens more were injured.

Hamka, a former worker at the smelter, showed New Lines and The Gecko Project images and video of the explosion and its aftermath, some of which had been shared on social media by workers. He pointed to the safety equipment used in the plant and played videos of workers ducking under showers of sparks from the furnaces, wearing paper masks and fabric boiler suits, rather than the reflective heat-resistant garments that are commonly used in Western smelters.

After the explosion in December, Hamka transported the body of one of the victims — a friend — back to his family. Workers weren’t supposed to speak to anyone from outside IMIP about the disaster but Hamka managed to reach his friend’s wife to arrange the trip. Like others we spoke to with knowledge of the accident, he attributed it to management’s desire for constant production, which meant cutting corners on safety. The furnace should have been fully shut down for a week to make it safe for repairs, Hamka says. “He was killed for the sake of a week.”

The accident at ITSS — or the widespread media coverage of it — prompted a flurry of investigations into safety conditions at IMIP. Inspections are supposed to happen routinely but workers and union officials say that they’re often cursory, or that companies are able to present an illusion of compliance to the authorities.

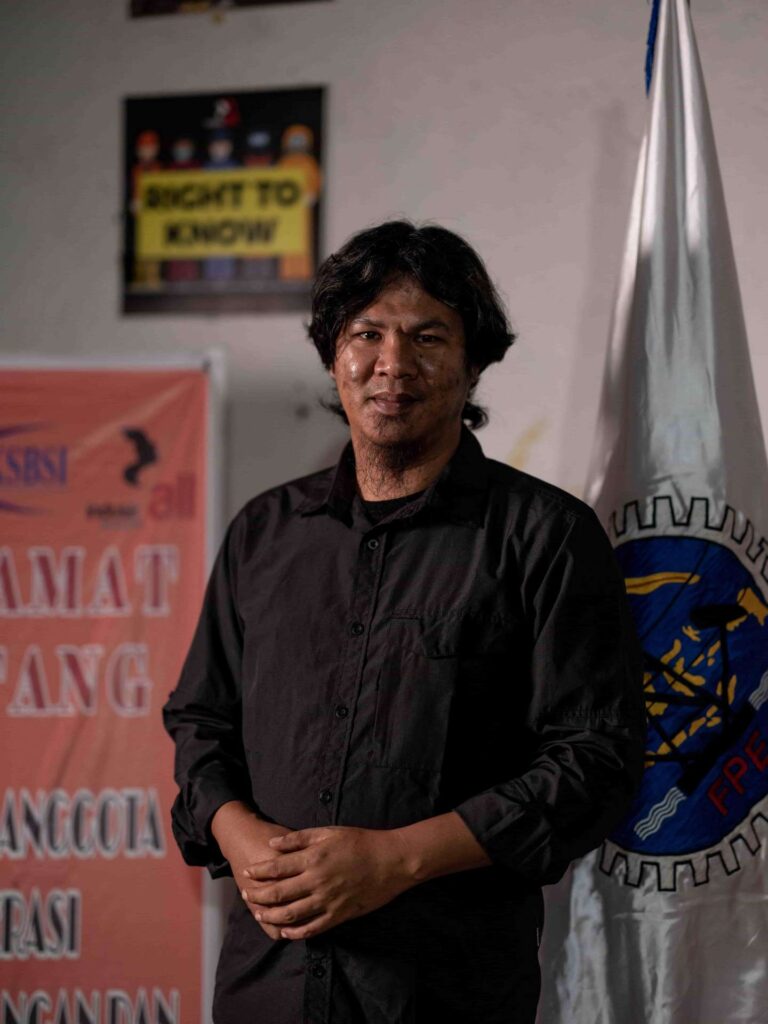

“The companies have 1,000 ways to bend the rules,” says Asri Sonah, the head of the Morowali regional office of the Mining and Energy Federation of the Confederation of All Indonesian Labor Unions.

One commonly ignored rule is particularly worrying, according to Asri. He says that Indonesia’s Ministry of Manpower rules make it compulsory for safety officers to be Indonesian nationals. That, however, is rarely observed in practice, according to workers and unions.

Workers at five different Chinese-owned smelters told us that safety policy was overseen by Chinese managers. Asri himself works on contract as a safety officer at IMIP tenant PT Dexin Steel, a joint venture between several Chinese-owned companies and IMIP’s owners. Many of his supervisors and superiors are Chinese, he says. He alleges that Chinese workers were often brought in on specialist visas to work in certain areas of the business but then moved around the company into other positions. After the deadly explosion at Indonesia Tsingshan Stainless Steel in December 2023, two Chinese employees were named as suspects in a police inquiry into the accident. According to Asri, the pair, who allegedly oversaw the repair crew caught up in the accident, were registered as members of the finance department.

Tsingshan Holdings Group, ITSS’ owner, did not respond to requests for comment.

The explosion in December is far from the only tragedy in the smelters. Workers tell us about colleagues crushed to death by black sludge; burns from leaks from furnaces operating at 2,700 degrees Fahrenheit (1,500 C); and lost limbs and eyes from sparks and conveyor belts. At another smelter north of IMIP — Gunbuster Nickel Industry (GNI), which is operated by Jiangsu Delong, owner of Virtue Dragon — two crane operators were burned to death in December 2022 after being trapped in their cab when a furnace blew up. One of them, Nirwana Selle, had often posted upbeat TikToks of her work at the plant. A video of the accident that killed her went viral on social media.

The ITSS accident was remarkable not just for the scale of its fatalities but because details about it spread beyond IMIP through social media posts by workers. CCTV footage of the blast found its way to TikTok. But when it isn’t forced upon companies by leaks and workers’ actions, there is little transparency in the industry. IMIP, by far the largest of the nickel processing centers, has to submit an annual report to the government detailing accidents and injuries, Asri says. But the report isn’t made public. “It’s classified,” he says.

In December 2023, the Ministry of Manpower said it was collecting data on accidents and potential breaches of labor laws at IMIP. The following month, the ministry said it was conducting inspections of ITSS’ facilities and practices.

Since then, there have been no further announcements. The Manpower Ministry did not respond to multiple requests for comment.

Emilia Bassar, a spokesperson for IMIP, said in an emailed response to questions that the park submits accident reports to the provincial and district authorities as required by law, that employees are routinely trained in emergency procedures and that “periodic inspections are carried out by internal and safety teams to assess the condition of systems and equipment and ensure the suitability of emergency procedures.” She also stated that IMIP reports accidents to a national social security scheme so that injured employees receive medical expenses and compensation.

The messaging from the central government has helped perpetuate workers’ concerns that their well-being is secondary to the needs of investors. In December 2021, Jiangsu Delong launched GNI in Central Sulawesi. President Joko Widodo cut the ribbon at its inauguration and gave a speech reminding local governments of their responsibilities to “make companies and investors feel safe.”

“We know Indonesia needs investment,” Asri says. “But just because you’re investing doesn’t give you the right to trample labor rights in the process.”

The sense that safety for companies has come at the cost of safety for workers has led to unrest within the industrial parks. In 2020, hundreds of workers at VDNIP clashed with police and company security personnel after a dispute over pay and safety conditions turned violent. Dozens of company vehicles were burned and buildings were set alight. In January 2023, at GNI’s new smelter in Morowali, Chinese and Indonesian workers fought each other with crowbars and sticks after another dispute over safety and wages spiraled out of control. Two people died. At both sites, VDNIP and GNI, more protests are planned, according to community organizers.

“The government needs to do something before there’s a worse accident,” says one engineer at a Chinese-owned smelter in IMIP, speaking on condition of anonymity. What keeps him awake at night, he says, is a 2-million-cubic-foot tank of carbon monoxide attached to the smelter’s coal-fired power station. If that breached, it could dump deadly gas over nearby houses.

IMIP spokesperson Bassar says, “To handle tank leaks that can cause exposure to [carbon monoxide] gas in high concentrations, the company is making mitigation efforts,” including installing real-time monitoring systems.

Opposite the Chinese accommodation at Virtue Dragon Park in Morosi is a row of low lean-tos made of wood and corrugated iron, battered by the heavy passing traffic, mud-caked and rusting. One shop sticks out — a clean, bright-fronted cafe with a sign advertising barbecued meat in English and Chinese. Inside is a near-perfect facsimile of a Chinese working-class roadside eatery, with fake bamboo veneers on the table, textured wallpaper and red paper lanterns on the ceiling. It serves skewers of goat, beef and chicken liver and handmade soup dumplings at twice the price of local dishes. The menus are in Chinese, with no translations into Indonesian. “It gets busy around 5 p.m.,” says the waitress — a local, who speaks a smattering of Chinese. When rush hour begins, the road outside jams up with yellow-helmeted workers on motorbikes. Chinese workers mill about the market stalls that sell fruit, dried goods and frozen food. A few stop for milk tea in the barbecue restaurant, resting their helmets on the tables.

As we leave, a trio of young Indonesian workers in VDNI overalls and helmets leaning on their mopeds calls out to us. “Hey,” one says, in English. “Fuck China.” He raises a middle finger and repeats it. “Fuck China.”

Chinese workers are often perceived by their Indonesian colleagues to get a far better deal than locals do. They’re typically paid more and tend to be placed in supervisory positions. That, according to workers we speak to, fuels a sense of injustice that occasionally manifests as rage. But there is also substantial evidence that Chinese workers in Indonesia have been subjected to abusive and exploitative practices.

The United States-based NGO China Labor Watch has interviewed dozens of Chinese workers over the past three years, documenting what it says amounts to large-scale forced labor in the nickel industry.

“There were a lot of Chinese workers who went to Indonesia under false promises from labor intermediaries, and when they got there, they found the conditions were quite different,” says Li Qiang, the founder of China Labor Watch. Restriction of movement is common. Workers at the bigger plants are often only allowed out of their dormitories for two hours a day. If they break curfews, they are fined. “And there are some plants where they just straight up can’t get out,” Li says.

Describing one of the clearest indicators of coercion, Li says, “It is basically treated as a standard practice for these companies to take away people’s passports.” That makes workers unable to leave of their own volition and means their employers have complete control over their immigration status.

In 2021, a Chinese news website, thepaper.cn, reported on a group of expatriate workers at Virtue Dragon, who alleged that their passports had been confiscated by their employers and that they had been shipped to Indonesia with visas that didn’t allow them to work legally in the country. Without regular immigration status, they were afraid to complain to local authorities about their alleged ill-treatment.

Social media posts seen by New Lines and The Gecko Project, apparently made by Chinese workers at other Jiangsu Delong companies in Indonesia, complain of delayed wages and poor living conditions in the dormitories where they’re housed — which they are reportedly only allowed to leave for a few hours a day outside of work hours. In May, workers confronted managers at GNI, claiming that their wages hadn’t been paid for five months. Workers were allegedly then threatened with arrest. In one video posted on Chinese social media at the time, workers confronted a supervisor wearing a GNI uniform, who said he “had no money” to give them. According to Li, these reported practices — coercion, deception, abuses of power and restrictions of movement — arguably meet the definition of modern slavery.

Li says that companies have been cracking down on social media use and punishing workers who post about accidents or other issues. “There are even cases where workers’ personal devices would be confiscated for a quote, unquote, ‘security check,’” Li says.

The image painted by Li and workers in Sulawesi stands in stark contrast to the prevailing mood of the media’s coverage of China’s so-called “Belt and Road” investments into Indonesia. State media have published dozens of stories about the overwhelming popularity of Chinese businesses, which bring jobs, opportunities and infrastructure to grateful local communities. One Xinhua story from 2022 gave a lyrical view of rush hour at the Indonesia Weda Bay Industrial Park in Maluku: “Cars and motorcycles merged into a traffic flow under the sunset and Indonesian employees walked together,” it read. “While walking and chatting, hearty laughter could be heard from time to time.”

The nickel frontier keeps on expanding. To make space for new industrial parks and mines, acre upon acre of forest is being cleared.

Diggers cut away at the coast.

To feed the parks, huge new power stations are being built. Their chimneys stand over the horizon, pumping out steam and fumes.

Chapter 3 | Sacrifice Zone

To reach Central Sulawesi overland from the southeast means crossing steep forested mountains where the road quickly deteriorates into rutted tracks. On the descent, the first sight of the coast and the Banda Sea arrives just before the plumes of the smelters come into view. Then, you are really into nickel country. Every few miles, side roads lead into construction sites and mining pits. On the seaward side are ports and jetties in various stages of construction, most of them guarded by signs: “Objek Nasional Vital” and “No Drone Zone.”

The only break in the chain is in a wide, flat bowl bridging the high ground and the coast between IMIP and the administrative center of Kolondale, where palm oil plantations stretch from horizon to horizon, an endless repeating pattern of cut-and-paste palm trees planted in parallel lines. Even the palms are now giving way to mines and smelters, a monolith replacing a monoculture.

Just south of Kolonodale, a new industrial park has been cut out of the forest — the Stardust Estate. We circle the park on its orbital dirt road, where terraced rows of worker dormitories are still under construction. Wooden stilt houses have sprung up in small settlements on the fringes of the park. Grey company overalls hang on washing lines. One small mine has already broken out from the perimeter and gouged into a sheer cliff behind a wall of oil palms. Inside are two large smelters, one owned by GNI, the other by Nadesico Nickel Company (NNC).

While GNI produces lower-grade nickel for stainless steel, NNC is a genuine piece of the battery supply chain, producing nickel matte, which is further refined in China into components for nickel batteries. Another Chinese company, CNGR Advanced Material Co., Ltd., a supplier of battery components to Tesla, is an investor in the business. Vapors from the factory’s smokestacks reach up to meet the low cloud and a skeletal line of conveyors stretches down to the coast, where barges unload mountains of coal to feed the furnaces.

The Indonesian government has relentlessly talked up the role that the nickel industry plays in the green transition. Nickel becomes cathodes (the parts of batteries that conduct electric charge), cathodes become batteries and batteries become electric vehicles, taking petrol vehicles off the roads worldwide. At the core of that vision for a cleaner, greener future, though, is an enormous compromise on carbon. The new smelters springing up across the country are mostly being powered by coal.

As a tropical archipelago, Indonesia is heavily exposed to the negative effects of global heating — its own capital city risks becoming uninhabitable as it sinks and sea levels rise. Projections based on current global emissions show that climate change will cost the country more than 4% of its gross domestic product. It is also an outsize contributor to those emissions globally, due to its carbon-intensive extractive industries, an electricity grid that is 60% powered by coal and the widespread destruction of its forests and peatlands.

In 2022, the Indonesian government promised that it would stop building new coal power stations and close many of its facilities early as part of a package of measures to reduce emissions, backed by a commitment by its international partners to raise $20 billion in funding. But a presidential regulation that had written these measures into Indonesian law came with an exemption for “strategic” industries. For the nickel smelters, who need a lot of power, that was a very convenient gap in the rules.

Nickel smelters in Indonesia tend to build their own “captive” power plants, private generating facilities that aren’t part of the electrical grid. As the smelters expanded between 2013 and 2023, captive coal power generation in Indonesia grew eightfold, to nearly 11 gigawatts, equivalent to nearly 10% of the country’s total installed capacity, according to research from the Centre for Research on Energy and Clean Air (CREA) think tank.

CREA found that at least another 14.4 gigawatts of captive coal power is currently planned or under construction, as of late 2023. According to Indonesian government statistics, coal consumption has jumped from the equivalent of 559 million barrels of oil in 2021 to 736 million in 2023.

The transition economy has given a startling shot in the arm to coal. “The argument we’ve heard,” says Katherine Hasan, a Jakarta-based analyst at CREA, is that coal “is the only feasible option,” especially since global emissions are still reaching a peak. “Maybe that’s seen as an opportunity. It’s the last hurrah.”

Many of the new coal power stations are owned and operated by the predominantly Chinese owners of smelter infrastructure, often with local partners. They are often set up as separate companies, however, seemingly to make it easier to attract financing, according to research from the NGO Trend Asia.

“It’s a loophole,” says Zakki Amali, Trend Asia’s research manager. “They will establish one subsidiary for the smelter, and another subsidiary for the coal power plant.” A bank will then “channel money into the subsidiary that doesn’t have the coal power plant.”

Research from Trend Asia and two other nonprofits, Recourse and Inclusive Development International, found that banks and international financial institutions that have pledged to stop funding coal power as part of their own climate change commitments have indirectly financed captive coal by supporting smelters in Indonesia, or by giving lines of credit to local banks who then go on to finance coal infrastructure. Indonesia’s commercial banking sector committed more than $3.5 billion in financing to coal companies in 2023, according to data collated by the German NGO Urgewald.

This financing blind spot means that other countries — principally China — are putting money into coal power in Indonesia, while decarbonizing industries back home. GNI’s latest captive power plant, “Delong Phase III,” was reportedly supported by finance from the Chinese state-owned Sinosure export credit company. In 2021, the Chinese government pledged that it would immediately stop financing the construction of coal power plants overseas.

Viewing the smelters up close — vast, soot-stained edifices belching steam and smoke — it is hard to see them as the core of a green industry. Indonesia’s nickel just happens to be concentrated on Sulawesi and in the Maluku archipelago, fragile environments known for their unique forests, coral reefs and mangroves. “These are very remote areas and very pristine,” Hasan says. “So you can imagine they’re not supposed to be disturbed. But you have the fuel for economic growth there.”

It is possible to power smelters using other sources. The Brazilian minerals company Vale runs smelters in Southeast Sulawesi on hydroelectric power and some Australian smelters rely on solar and wind. But these are expensive. Coal is cheap in Indonesia and easy to transport.

The types of nickel ore that make up Indonesia’s reserves exacerbate the problem. Battery-grade nickel is usually made from sulfide ores. Indonesia only has laterite, an ore much harder to process, which is more commonly turned into nickel pig iron, a component of stainless steel. Processing laterite into the nickel matte that is then processed further to be used in batteries using an increasingly common — if controversial — technique, known as high pressure acid leaching, is nearly twice as carbon-intensive as processing nickel sulfide, according to data from the International Energy Agency. Some producers, including Tsingshan, the co-owner of IMIP, have begun processing nickel pig iron into nickel matte, which is nearly three times as carbon-intensive as that.

In May, Luhut Binsar Pandjaitan, Indonesia’s coordinating minister of maritime affairs and investment, wrote an op-ed in Foreign Policy magazine defending the use of coal in the nickel industry. In the piece, Luhut, who did not respond to a request for an interview, articulated how the government sees the pivotal compromise behind the industry. “Many Indonesian smelters are powered by coal. For some, that means any battery containing its refined nickel is discredited, despite the net carbon benefit of taking combustion engines off the road,” he wrote. “Such climate purity breeds inertia and is ultimately self-defeating. Environmental trade-offs are as critical to the green transition as nickel is to the batteries that will power it.”

The central government has done little to push smelters onto other power sources. The only concession to the need to decarbonize the industry is a provision that new captive coal power stations at nickel smelters are supposed to be decommissioned by 2050. By then, though, Indonesia’s nickel assets will be close to depleted. The Indonesian Nickel Miners Association said last year that high-grade ore reserves may be exhausted by 2029 and that, unless substantial new deposits are found, lower-grade ores are likely to run out in 33 years’ time. Smelters have every incentive to move as fast as they can while the rules are lax, their tax breaks hold and the ore is cheap and available. They have little incentive to invest for the long term. The timescales of the industry mean that the vast majority of nickel mined in Indonesia will be processed using coal power.

Trend Asia’s Zakki says this isn’t a transition for Indonesia itself but rather “Indonesia is helping China to transition.”

While the environmental impacts of coal power can feel distant and abstract, on the ground they are tangible. With the furnaces firing all day and night, coal dust blows in flurries in the settlements around Sulawesi’s smelters and the air is thick with particulates and the gases from the chimneys, which burn on the back of the throat. It is worse at night, when, according to smelter workers, the plants release toxic plumes of sulfur. One engineer at IMIP says that his own coal power plant skimped on filtration technologies that could reduce the amount of dangerous pollution. “The technology is used in China,” he says. “But not here.”

Another worker we speak to, Hamka, was employed at IMIP cleaning out the filters that sit below the chimneys, sifting out particulate matter from the coal burners and furnaces. Each day, he clears the larger particulate matter out so it can be used as construction material and, at dawn, dumps the smaller particles into the chimney to be blown out over the town surrounding the park. “Regarding the problem of air pollution, I am the perpetrator,” he says.

Around every smelter complex we visited, residents complained of breathing problems and a rise in respiratory infections. CREA warns that, based on its analysis, air pollution from smelters and captive coal plants could cause more than 5,000 deaths per year in Southeast and Central Sulawesi by 2030.

The concentration of pollution and the accompanying impact on health in the regions around the smelters have led some, including Zakki, to a grim conclusion: that Morowali, Halmahera, Morosi and other centers of Indonesia’s green transition metals industry are being abandoned to the accumulated negative impacts of the business. By concentrating the consequences of mining and smelting — and the compromises on safety and security — out of sight at the end of the supply chain, companies and consumers can enjoy the benefits of the transition without having to reckon with the costs.

“Indonesia is becoming a sacrifice zone for China,” he says.

IMIP stated that it continues to invest in environmentally friendly technologies and uses filtration processes to reduce the level of pollutants being released through its chimneys.

The Indonesian government promises that the cost of the nickel rush is justified, arguing that the money flowing in will create jobs, and position the country as a leader in the green transition.

But the compromises it has made to build the industry cast a shadow over its future.

Chapter 4 | The Bargain

The low-rise sprawl around IMIP has the peculiar mania of a frontier town. At 4 a.m., the call to prayer blares out at earbleed volume over motels housing the town’s growing population of sex workers. Makeshift fish and fruit markets sit cheek-by-jowl with phone shops, jewelry stores, sportswear outlets selling suspicious branded goods, safety goods stalls with stacks of yellow helmets and tailors with mounds of gray overalls in for repair. For long stretches, the only permanent structures are Indomaret and Alfa convenience stores, surrounded by wood and corrugated-iron lean-tos, all divided from the dirt road by a deep drainage ditch and reached by plank bridges. In others, there are smart coffee shops and blacked-out billiard halls. On one street, the white logo of a fake Apple store shines out on a black corrugated-iron background.

In the grand bargain of the nickel rush, IMIP is what the Indonesian government sees as the credit column, set against the social and environmental cost. At night, the high ground above the town — which is really a series of villages that have been subsumed into the whole — glows from the clustered furnaces. When we visit, we find places that Google Maps’ satellite images still shows as forested hills, which are now industrial yards with steaming chimneys and long ore and coal stores. New offshoots of the main settlement follow the developments up the hillsides, populating muddy stretches of road with small stores and boarding houses.

The park now has 54 tenants working in the nickel industry, employing around 100,000 people, who have come to Southeast Sulawesi from all over Indonesia on the promise of a decent wage and a chance to participate in the country’s boom industry. Alongside the workers who fear for their safety and advocate for better working conditions and wages, we meet employees still sanguine about the industry. One, who has left the uncertainty of a career in journalism to work in a smelter, describes his joy at watching the sparks fly from the furnace — and at his regular paycheck.

On purely financial metrics, the nickel rush has been a roaring success. Government statistics and customs data show that foreign direct investment in the metals and mining sector jumped from just under $8 billion in 2020 to more than $16 billion in 2022. Nickel exports reached $22 billion in 2022, a 16-fold increase since the first export ban in 2014. The massive expansion of the industry has put Indonesia in an even more dominant position in nickel than it held a decade ago, producing more than 40% of global output. The sheer volume of Indonesian nickel flooding the markets pushed prices down by more than 40% in 2023 and forced producers in other countries to the wall.

This is only supposed to be the start. The majority of Indonesian nickel still goes into steelmaking, but the grand plan for the industry envisions a high-tech manufacturing sector with electric vehicles rolling off production lines and into Jakarta’s eternal gridlock. The country’s first EV battery factory, a joint venture between the Korean companies LG and Hyundai, also in Java, opened in July. BYD, the Chinese EV giant, announced in January this year that it would build an EV plant in Java, a major coup for the government — although most of the models that BYD sells in Southeast Asia don’t use nickel in their batteries, preferring more stable lithium-iron-phosphate cathodes.

The government’s vision is a compelling one, which has allowed it to argue that the short-term impact of the industry can be weighed against its role in securing a cleaner future.

The history of the nickel policy extends back beyond the battery sector, says Putra Adhiguna, managing director of the Energy Shift Institute, an energy and finance think tank. “But if you’re looking at how the government is constructing the story, it’s all batteries. … It’s the golden ticket that the government is using. They’re basically saying: For Indonesia to prosper in the EV transition, we will do it at any cost.”

On the current trajectory, that future is still some years away. And, some experts warn, the choices that Indonesia has made to propel the rush at speed could end up cutting its industry out of some of its most important markets.

The vast majority of foreign investment that’s gone into the nickel industry in Indonesia has come from China, and Chinese companies are deeply, even inextricably, embedded throughout its infrastructure. That is a big problem for the U.S., which is concerned about relying on China for critical minerals. Relations between the two superpowers have deteriorated over the past decade and the U.S. is trying to decouple its supply chains from China. Nickel and other battery components are of particular concern.

Earlier this year, Ashley Zumwalt-Forbes, the U.S. deputy director for batteries and critical minerals, summed up her government’s concerns about the way that Indonesia has handled its nickel business in a LinkedIn post about the collapse of several Australian nickel miners, after prices fell due to oversupply of Indonesian nickel. “The global nickel situation is dire and it is, in my view, an extreme threat to national/international security as well as the environment,” she wrote, adding that “the grip of (dirty) Indonesian nickel on the market” will further concentrate critical metal supplies into the hands of what Washington calls “foreign entities of concern” — potential enemies of the U.S., including China.

Alongside sweeping sanctions on technology exports, the U.S. has used domestic policy to try to cut China out of its supply chains. The Inflation Reduction Act, a huge piece of legislation aimed at supporting the American transition to a more sustainable economy, offers subsidies to EV companies — but not if they include materials or components made in China or by Chinese companies.

To get around this restriction and gain access to U.S. markets, Indonesia has been lobbying for a limited free trade agreement with the U.S., focusing on transition minerals. However, it has faced opposition from American lawmakers concerned at the litany of ills unfolding on Sulawesi and other islands. In October 2023, a group of U.S. senators wrote an open letter opposing such an arrangement, citing Indonesia’s poor record on labor rights and community engagement, the environmental and ecological damage caused by the sector and its high carbon emissions relative to other producing countries, such as Australia and Canada. The letter also pointed to China’s dominance of the industry, noting that, of 25 planned refineries for battery-grade nickel, all but three involve Chinese companies.

Luhut’s Foreign Policy article, which lambasted the senators’ resistance to a free trade agreement, did not directly rebut the letter’s claims, arguing instead that the environmental trade-offs are necessary for America to get EVs on the road. “Cheaper inputs mean cheaper batteries. Free from artificial trade barriers, refined nickel from Indonesia is competitive because coal is abundant in the country,” he wrote. If the U.S. wants cleaner nickel, it should invest in Indonesia and improve its standards. If it doesn’t, he implied, it will push Indonesia into an even closer relationship with China. “Ultimately, Indonesia’s nickel will be exported somewhere.”

In September, the U.S. added another accusation to the charge sheet. The Department of Labor issued a report on global child and forced labor, which highlighted concerns over the conditions for workers in Indonesia’s nickel industry. One section focused on the way that Chinese workers were recruited, echoing the findings of China Labor Watch’s research.

In Europe, another major end market, lawmakers are increasingly concerned about the embedded environmental and social issues in their companies’ supply chains. In April, the European Parliament ratified a new forced labor regulation, which will allow member states to seize and destroy products shown to have forced labor within their supply chains. A new EU Batteries Regulation came into force last year, mandating that, by August 2025, any company with a turnover of more than $44 million that sells batteries or products with batteries in them will need to have an independently verified due diligence policy on environmental and social risks in its supply chain, all the way back to its raw materials. By 2027, electric vehicles sold in the EU will need to have battery passports, which show where their principal components were sourced from and the carbon emissions resulting from their manufacture. That would include any Chinese-made vehicles from BYD, SAIC or Geely, all of which are trying to crack European markets.

“The requirements that are in the regulation are far-reaching,” says Andrew Britton, the founder of sustainable supply chain consultancy Kumi. In places like Indonesia, they require due diligence down to the mining level. While he believes the success of the regulation will be in its implementation and industry is likely to push back on it, Britton says that the requirements are “unprecedented. … Industry has never had to deal with anything like this.”

There is anecdotal evidence that European firms are paying attention. Workers at IMIP, including union members, told New Lines and The Gecko Project that they had met with delegations from German carmakers, who had visited the park after the high-profile accident in December 2023 to look into labor issues. In June, the French miner Eramet and the German chemicals company BASF pulled out of a $2.6 billion nickel-cobalt smelter project at the Weda Bay industrial park, without giving any public explanation.

What that means is that Luhut’s equation — “cheaper inputs mean cheaper batteries” — isn’t guaranteed to hold if regulatory and social pressure grows over labor issues, environmental damage, carbon emissions and geopolitical entanglements.

For the past few years, Indonesia has intentionally kept nickel prices low by flooding the market with its products — at one stage, the government even proposed creating an OPEC-style cartel for the mineral. Officials have said that the ideal price for nickel is around $18,000 per ton. At that level, it’s cheap enough that EV makers will choose to use it in their batteries instead of other technologies, such as lithium-iron-phosphate cathodes. Nickel contracts on the London Metals Exchange have often dipped below $16,500 over the past two years — a price at which much of global supply is not economically viable.

That need to keep prices down has motivated some of the choices made in the industry, according to analysts and economists. It is partly why the industry is so dependent on cheap coal power and why the government has deregulated to such an extent that environmental standards have dropped. On the margins, it has pushed miners to try to cut corners, according to Bhima Yudhistira, executive director of the Center of Economic and Law Studies, an Indonesian think tank. The same is true, he alleges, of the smelter companies, some of whom, he says, have told him they see their investments in Indonesia as time-limited, once reserves of the mineral start to dwindle. High-grade reserves will likely be spent within a decade and lower-grade reserves will be harder to refine profitably. “They want to play fast and efficient. They think that the Indonesian nickel boom will not last,” Bhima says.

Nickel is an important mineral for battery makers but it’s not their only option. Some countries have become so complex and risky for buyers that they have reorganized their supply chains to avoid their main exports. Notably, in the Democratic Republic of Congo (DRC), concerns about human rights abuses in the cobalt supply chain led companies to move away from cobalt-based batteries, according to Aimee Boulanger, executive director of the Initiative for Responsible Mining Assurance (IRMA), a nonprofit that works with mining companies and communities on sustainable mining practices.

“I think Indonesia has the DRC to look at. That’s a place that a whole bunch of end brands are buying around,” Boulanger says. “Cobalt already showed how if the material gets so difficult and so controversial, even the chemistry of what goes into the battery can be shifted.”

Boulanger says she has seen signs that companies and officials in Indonesia are starting to take note of the concerns downstream in the automotive industry. Her organization has its own, internationally recognized standard for miners, which marks their operations on social and environmental metrics. Boulanger says that at least one Indonesian miner has approached IRMA asking how to increase its score — because global carmakers’ expectations are now substantially higher.

She says that she thinks companies are realizing that their bottom lines may suffer if they continue operating with a reputation for human rights abuses and in places where fisheries are being contaminated. She sees a unique opportunity emerging, “for a fragile but important alliance between brands of the private sector and civil society to be asking for the same things.”

In Diana’s village, the promise of a new, greener, more vibrant economy feels alien.

The community remains under siege, trapped on a shrinking sliver of land, waiting for compensation.

Chapter 5 | No Going Back

The last “sope” boatmaker in Morombo died in 2024. The Bajau in the village were already fixed to the shore. Two generations have been born on land. But his passing marked another definitive severance from the past.

What is often not captured in the reckoning of the nickel industry is what comes after the mineral wealth is finally exhausted. The rush has descended quickly on economies and cultures that have endured for decades, even centuries, and caused damage that might take generations to repair.

Morombo is rare in Sulawesi in that it is one of the few places where pollution data has been collected over a long enough time period to fully demonstrate the impact that nickel is having on the ecosystem.

Laode Aslan, a professor of fisheries and marine science at Halu Oleo University in Kendari, used to travel to the area regularly as part of his studies. Aslan’s speciality is seaweed — he sits on a national commission for developing it as a crop, has designed training programs for farmers and tried to establish a seaweed economic zone in Southeast Sulawesi. North Konawe used to be a major center for seaweed cultivation, exporting the crop around the country and internationally. If you wanted to grow samples, that’s where you went. In 2015, Aslan went with a group of 30 students and “a ton of seaweed seedlings.” They planted them as they normally would and monitored their progress. For the first month, they barely grew at all and many died. “We cut the project short at less than 45 days,” he says. “We figured, why bother if it’s not growing?”

Stern and bespectacled in a batik shirt and baseball cap, Aslan speaks from his lab, surrounded by Erlenmeyer flasks capped with tinfoil, all holding spindly green fronds or yellowing smears of seaweed. The failure of the seaweed was a mystery, he explains. “I didn’t think that this was the impact of the waste from nickel mining,” he says. “At the time, no one cared about that.” He soon made the link, though. Aslan and his students tested their samples and found high levels of heavy metals — lead, copper, zinc, chromium and nickel, all consistent with pollution from mine tailings.

Late last year, he went back. The seaweed industry had entirely collapsed, he says. He took more readings. The data, which he shares with us, shows that levels of heavy metals had increased 40-fold since 2015. Livelihoods based on aquaculture and agriculture are becoming untenable there. “I don’t want to say it’s too late,” he says, but he admits that, at current rates of damage, there could be no way back. “In 10 or 15 years’ time,” he says, “it’ll be like an atomic bomb has gone off.”

Diana, the village elder, talks with great animation about the life she used to lead on the boats. In the dust on the floor of her house, she draws a schematic of the sope she lived on, the sleeping area, the small kitchen, the deck where the family gathered to eat. She shows how she would open clamshells with a metal spike and talks about how the boats would come to shore to trade octopus, cuttlefish, fish and clams for coffee and other goods. Now, she says, they’re not just poorer than they were, but disempowered — passive observers of a rush that has washed over them and left them in a space that is physically shrinking around them, waiting for the dust money to come.

“We ask for it today, and they say tomorrow,” Diana says. “Tomorrow we ask for it, and they say the next day.”

Adi Renaldi and Tracy Wen Liu contributed additional reporting to this story.